It is available in our product range as spiral welded and micro pilling as the static carrier of vital ports, breakwaters, and dock constructions in prestigious world projects.

All technical information about our products is always at your fingertips!

With the quality and dedication to meet the needs of our business partners in the best way

It is available in our product range as spiral welded and micro pilling as the static carrier of vital ports, breakwaters, and dock constructions in prestigious world projects.

For Spirally Welded Pipes

Outside Diameter

508 mm - 3.048 mm

20’’ - 120’’

Wall Thickness

5,16 mm - 25,4 mm

0,203’’ - 1000’’

Length

Single lengths up to 55,0 m

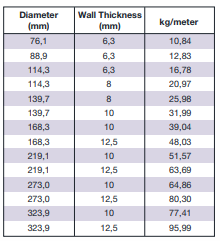

For ERW Micro Pilling Pipes

Outside Diameter

21,3 mm - 339,7 mm

1/2” - 13 3/8”

Wall Thickness

2,8 mm - 12,7 mm

0.110’’ - 0.500’’

Length

6,00 m - 18,30 m

19.69 ft - 60.04 ft

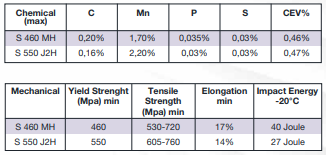

EN 10219-1 Grade including S355 J2H, CE marking according to S355, S460 MH, S550 J2H

ASTM A252 Grade, including Grade 3

The inner weld bead removed.

• Dual Layer Abrasion Resistant FBE OD Coating: API 5L7, CSA Z 245-20, NACE RP 0394, AWWA C213

• FBE (Fusion Bonded Epoxy) OD Coating: API 5L7, CSA Z 245-20, NACE RP 0394, AWWA C213

• Polyethylene OD Coating: DIN 30670, TS 5139, NF A 49-710, UNI 9099, EN ISO 21809-1

• Polypropylene OD Coating: DIN 30678, NF A 49-711, EN ISO 21809-1

• Epoxy ID Coating: AWWA C 210 Dual Layer Abrasion Resistant FBE OD Coating: API 5L7, CSA Z 245-20, NACE RP 0394, AWWA C213

• FBE (Fusion Bonded Epoxy) OD Coating: API 5L7, CSA Z 245-20, NACE RP 0394, AWWA C213

• Polyethylene OD Coating: DIN 30670, TS 5139, NF A 49-710, UNI 9099, EN ISO 21809-1

• Polypropylene OD Coating: DIN 30678, NF A 49-711, EN ISO 21809-1

• Epoxy ID Coating: AWWA C 210

BS EN ISO 12944-5.2019

Paints and varnishes. Corrosion protection of steel structures by protective paint systems.