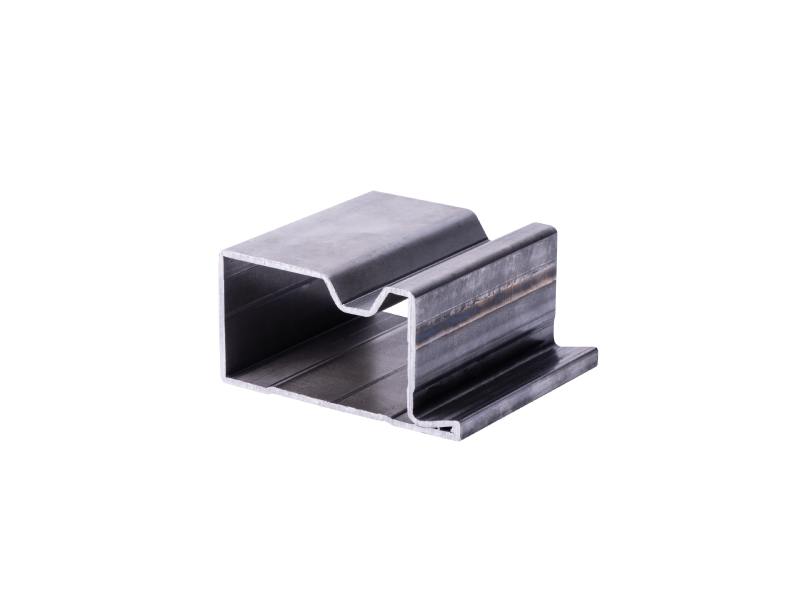

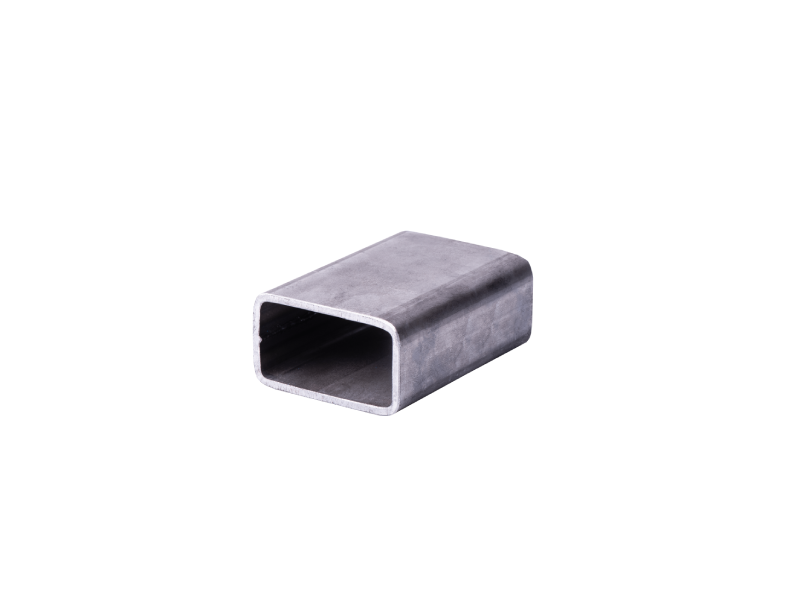

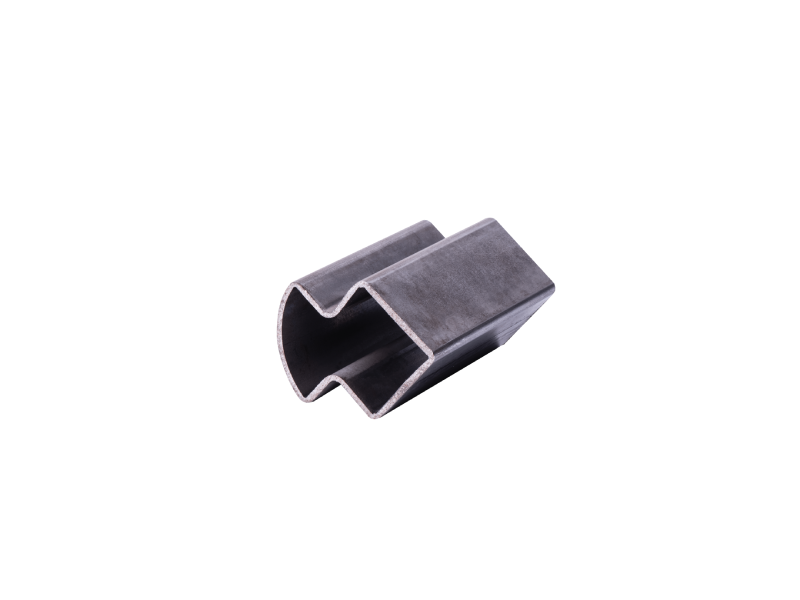

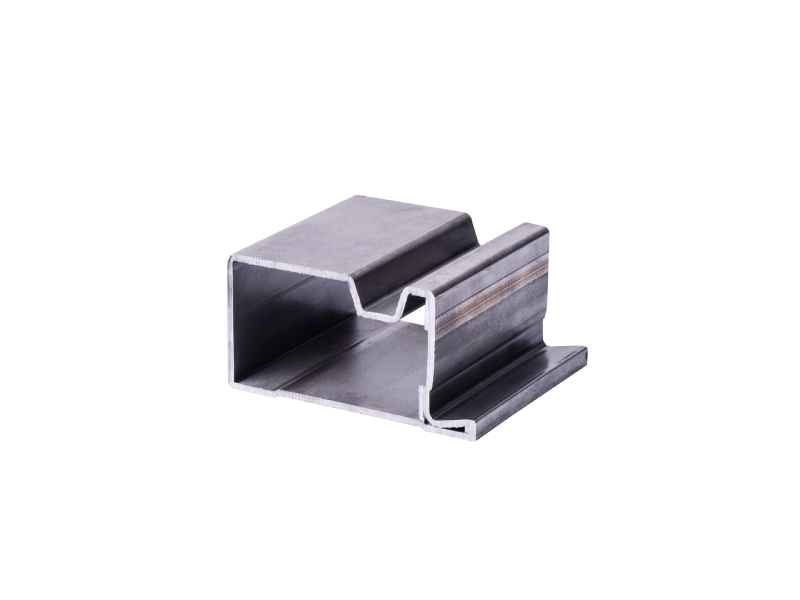

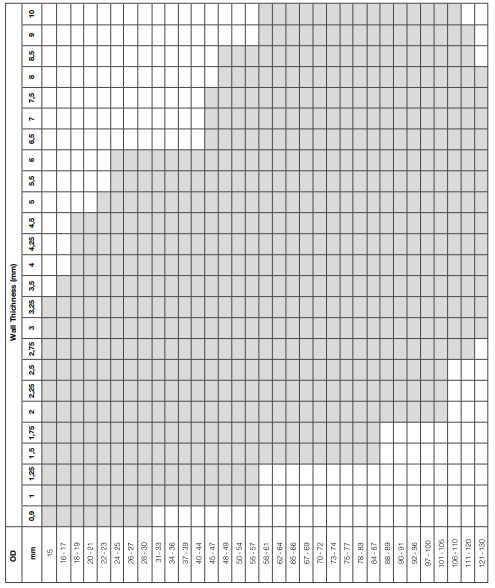

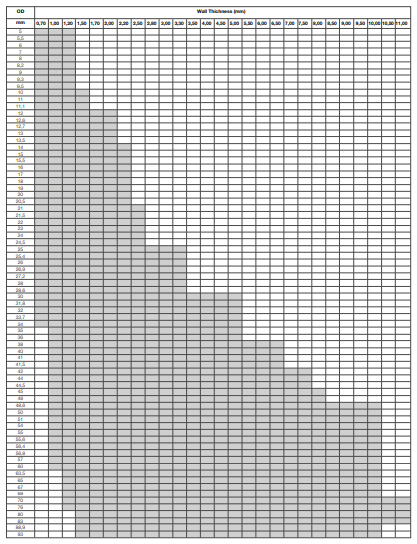

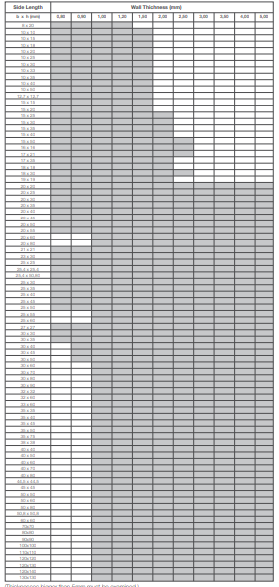

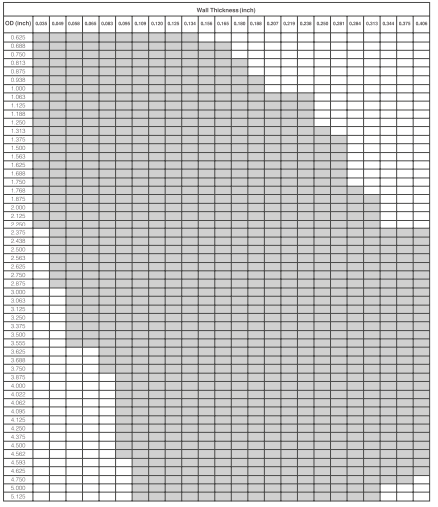

We are ready to produce according to different types of standards and/or customers' specialized technical requirements. Steel grades, wall thickness, dimensions, and tolerances may vary according to the requirements of the final product. Different pre-coated raw materials and final coating methods are available upon request.