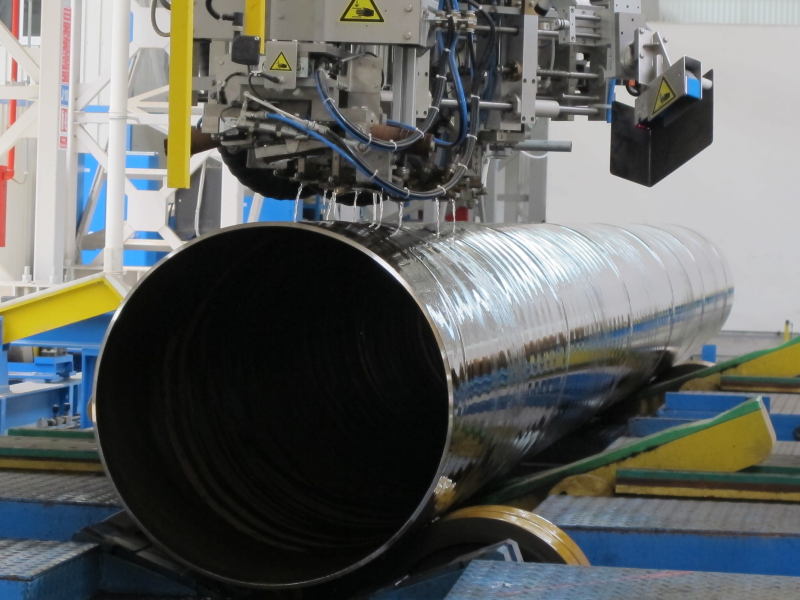

Spiral Welded (HSAW) Line Pipes, which are customized for different usage areas and produced with minimum tolerance in accordance with quality standards, can be produced with wall thickness, diameter, and coating options as required by the project or usage area. We remove Spiral Welded (HSAW) Line Pipes from our production line, which has many coating options such as epoxy, polyethylene, and polypropylene, with the quality and dedication that best meet the needs of our customers, and deliver them with different delivery options. In the supply of raw materials in Spiral Welded (HSAW) Line Pipe production, steel raw material (P195, P235, and P265) with a homogeneous material structure, reliable and correct mechanical properties, and high toughness is used. The raw material we use has traceability from the beginning to the end of the process.