It is NSF (National Sanitation Foundation) and DVGW (Deutscher Verein des Gas- und Wasserfaches) certified. Thanks to the certificates it received in North America and Germany, it can be used in drinking water installations and is safe.

All technical information about our products is always at your fingertips!

With the quality and dedication to meet the needs of our business partners in the best way

It is NSF (National Sanitation Foundation) and DVGW (Deutscher Verein des Gas- und Wasserfaches) certified. Thanks to the certificates it received in North America and Germany, it can be used in drinking water installations and is safe.

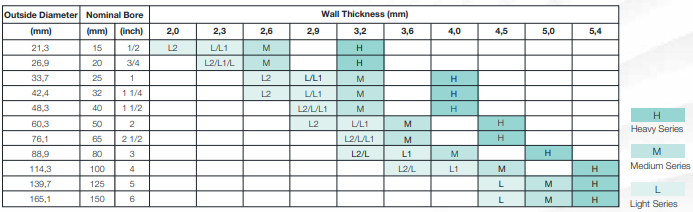

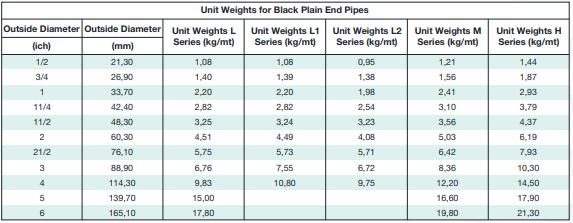

Outside Diameter

21,3 mm - 339,7 mm

1/2’’ - 13 3/8’’

Wall Thickness

2,0 mm - 12,7 mm

0,079’’ - 0,500’’

Length

3,00 m - 18,30 m

9,8 ft - 60 ft

• Production Norms

EN 10224, EN 10255, ISO 65, ASTM A 53, ASTM A 795, ASTM A 589

• Galvanizing Norms

EN 10240, EN ISO 1461 (BS 729), ASTM A 53, NFA 49-700, UNI 5745

• Production Standard For Threading and Coupling (1/2’’-6’’)

ISO 7/1, ANSI B.1.20.1, EN 10255

• Grooving (3/4’’-12’’) according to Victaulic Standard.

• Our medium series pipes can be used up to 25 bar operating pressure for water.

• Material Qualities

DIN 17100 St 37, St 44, St 52

EN 10025 S 195, S 235, S 275, S 355

Gr A, Gr B

• Visual and Dimensional Inspection

• Leak tightness testing: Hydrostatic Test, Eddy Current Test

• Destructive Tests: Flattening, Bending • Mechanical Tests

• Chemical Analysis • Metallographic Examination

• Others as required by the standards

• Ultrasonic weld seam test if applicable for gas pipes

• Mill Test Certificates - Issued upon request according to EN 10204 2.1; 2.2; 3.1; 3.2

• NDT Standards: - ET (EN ISO 10893-2), ET (ASTM E309)

• UKCA Certification

• Plain end (square cut or bevelled)

• Threaded and coupled (Max OD: 168.3 mm)

• Grooved

• Outside protective coating (black or red vanished) • Temporary oil application

(Other colors are available upon request.)

• Hot dip galvanizing

• PE, PP Coating

• Bare Pipe (Uncoated)

• Temporary oil application

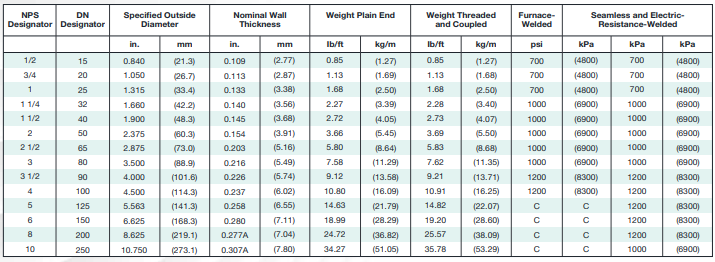

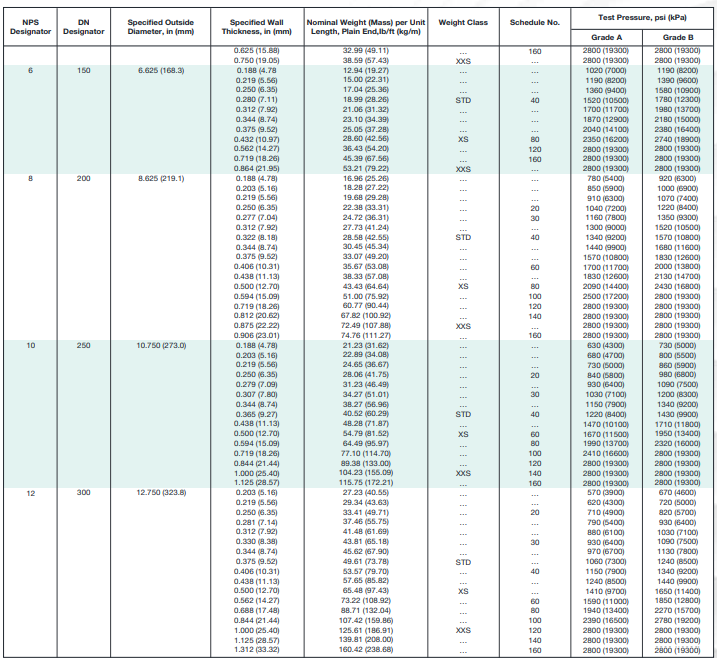

TABLE X2.2 Dimensions, Weights (Masses) per Unit Length, and Test Pressures for Plain-End Pipe

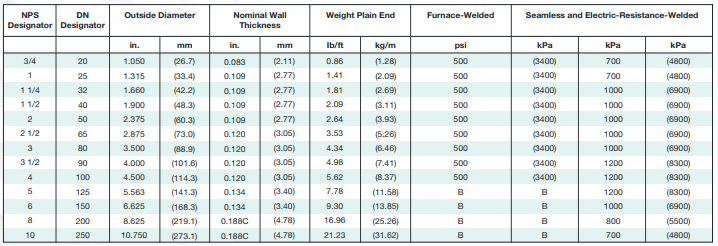

TABLE 1 Dimensions, Weights, and Test Pressure For Light -Weight Fire Protection Pipe- Schedule 10

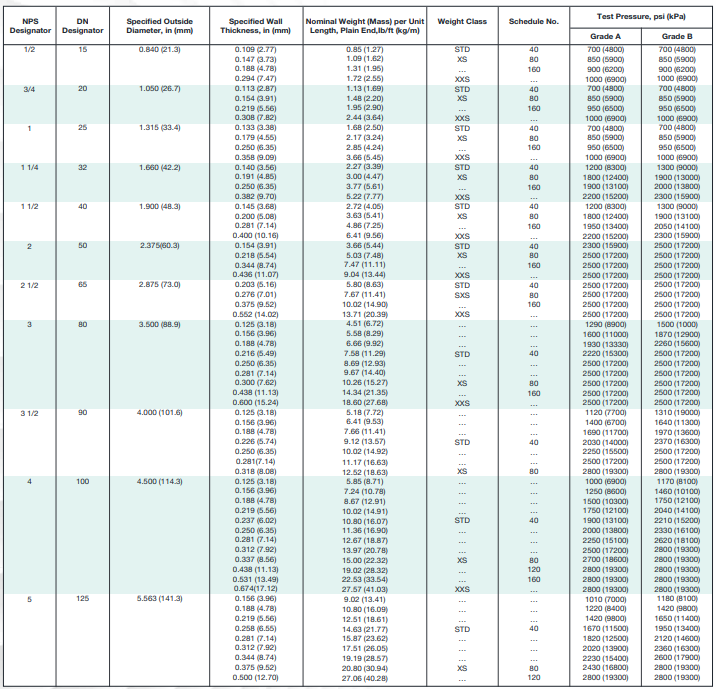

TABLE 2 Dimensions,Weights, Test Pressures For Standard-Weight Fire Protection Pipe -Schedule 30 and Schedule 40