ERW Line Pipes, which are customized for different usage areas and produced with minimum tolerance in accordance with quality standards, can be produced with wall thickness, diameter, and coating options as required by the project or usage area.

All technical information about our products is always at your fingertips!

With the quality and dedication to meet the needs of our business partners in the best way

ERW Line Pipes, which are customized for different usage areas and produced with minimum tolerance in accordance with quality standards, can be produced with wall thickness, diameter, and coating options as required by the project or usage area.

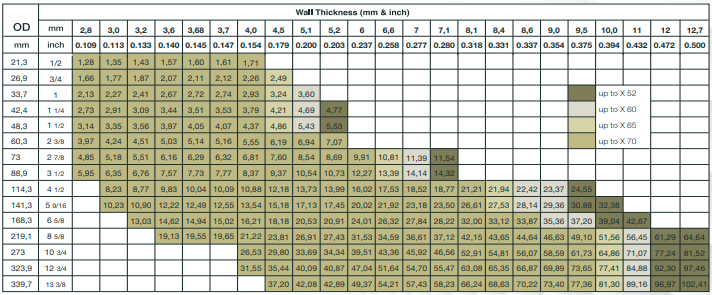

Outside Diameter

21,3 mm - 339,7 mm

1/2’’ - 13 3/8’’

Wall Thickness

2,8 mm - 12,7 mm and for US mill up to 15,88 mm available

0.109” - 0.500”

Length

6,00 m - 18,30 m

19,68 ft - 60,04 ft

Please ask for shorter lengths

• Visual and Dimensional Inspection

• Mechanical Tests: Tensile, Flattening, Expanding, Bending Weld Ductility, Fracture Toughness, PP, PE Testing

• Metallographic Examination Purity Analysis

• Chemical Analysis

• Hydrostatic Test

• Non Destructive Inspection: Eddy Current, Ultrasonic Test (Weld Check), Ultrasonic (full body, optional)

• Mill Test Certificates Acc. to EN 10204 2.1; 2.2; 3.1; 3.2

• NDT Standards UT (EN ISO 10893-11 Level U2), ET (EN ISO 10893-2 Level E2), API, EN ISO 3183, CSA Z.245.1

114.3 mm≤OD≤323.9 mm: API 5L

(Line Pipe according to API 5B)

Plain End-Square cut or bevelled / Zaplok

Black self colored / uncoated

Mill protective coating (black varnish) on outside surface

Epoxy lining and coating (AWWA C210), API RP5L2

3 Layer PE coating (DIN 30670, ISO 21809-1)

3 Layer PP coating (DIN 30678, ISO 21809-1)

21.3 mm≤OD≤88.9 mm: full body

114.3 mm≤OD≤323.9 mm: weld seam

21.3 mm≤OD≤168,3 mm:: off-line heat treatment.